top of page

Design Process

Backstory

The summer before working on this project, I lived in Colorado. While there, I spent much of my time rock climbing. On my first day out, we decided to frequent one of the most popular climbing areas Clear Creek Canyon. During this trip, the group climbing next to us suffered one fatal injury and a life altering injury. As a Wilderness First Responder, I worked with my partner (an E.M.T.) to assist the injured and call for help.

This is where I watched the injured await a rescue, and comforted the child they had came with. A five minute uphill scramble turned into a four hour rescue mission, in a moment when every minute mattered.

Highly trafficked areas deserve proper path systems to support universal access, natural environment, and safety. As a designer, I couldn't shake the thought that we can do better.

Research

Observational Research

This project began with an interest in using generative design to create walkway structures that encourage both environmental health and universal paths in nature. However, immense research took it in a new direction.

Conceptual Framework

Turning observations into framework provided solid direction for a concept to develop. The focus of my framework was Path structure and aesthetic.

Features Benefits Analysis

Designs will always affect their surroundings. Understanding the system they will be placed in and visualizing how they will alter it requires care. This graphic looks at what the product should include and why.

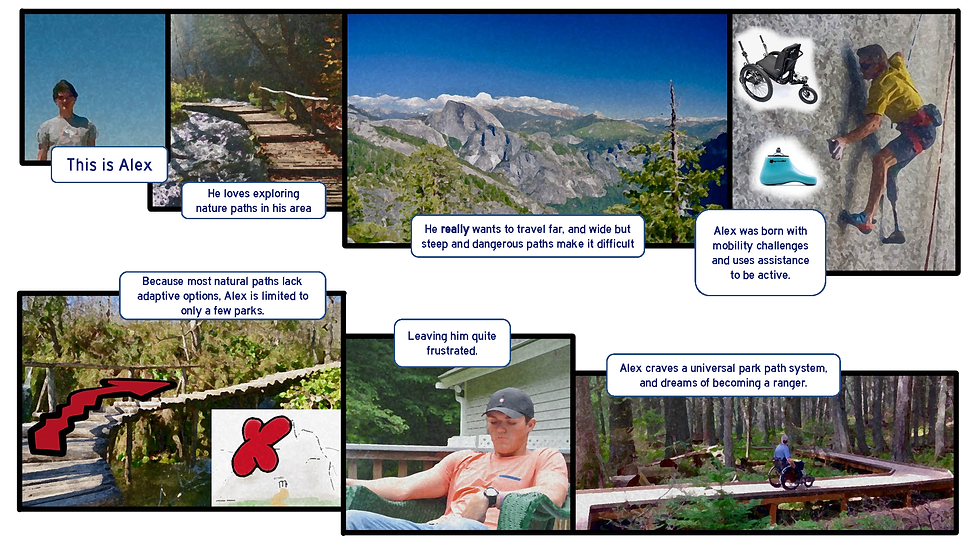

Experience Storyboarding

The last piece before diving into market is empathizing with users, a key step to the success of any project.

Product Board

The last component is market research. A design engineering comprehensive dive is needed to understand products that fit a similar design schema. Following this up with outside sources of inspiration prepare me for concept sketching.

Research

Design

Design Process

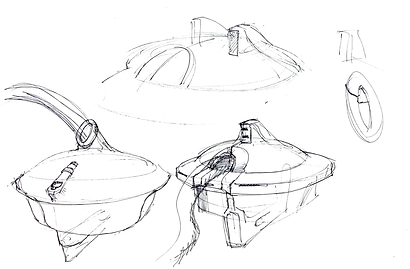

Concept Sketching

While continually referring back to research, I began ideation. I start with the structure but moving into the creation process of structure.

1. Understanding nature to use it within the structures.

2. Generative prints and packed earth designs.

3. Switching into construction process.

4. Printing drone and pump ideation begins.

5. Final drone direction found.

6. Mobile bio-concrete pump with design heavy form ideation.

7. Track and mulching area are incorporated.

8. Fiberglass upper with roll cage is settled upon for upper.

CAD

This immense structure involved over 2,000 components, and I have many to thank for sharing models, such as the exact full diesel engine I was looking for. The mixer, dual piston hydraulic pump, mixing agitator, fiberglass cover, roll cage and bottom structure were all made by myself using both Fusion 360 and Solidworks.

Design

The Bio-path is a redesigned concrete pump capable of 3D printing universal paths compliant with ADA guidelines in diverse and challenging terrains.

Use Storyboard

1.

Using the rear control panel, Bio-path is driven to the work site.

2.

Height adjustable poles are staked for the print droid to work on.

3.

Steel cables are added for the droid and it begins with an initial pass to create a 3D topography mapping.

4.

The bio-cement hose is connected and the droid begins it's path print.

Key Components

Bio-path is capable of pumping five hundred and fifty vertical feet and is designed to function with land erosion at worksite and limestone producing material to create biodegradable and emission friendly concrete.

Double muffler system

Lightweight mount cage

Repairable fiberglass cover

225HP six

cylinder engine

Erosion hopper

Dual cylinder

hydraulic pump

forged steel treads

Palm and traction movement reel

Lidar Scanner

Print nozzle

Antenna

Stability frame

bottom of page

![urodidae-cocoon-5[6].jpg](https://static.wixstatic.com/media/464605_4eb1f5da375346f190e93032142b8b7e~mv2.jpg/v1/fill/w_235,h_156,q_90,enc_avif,quality_auto/464605_4eb1f5da375346f190e93032142b8b7e~mv2.jpg)